LabRepCo PRECISION Series 49 cu. ft. Laboratory Freezer (-30/35C) | Auto Defrost

Item#: LP-49-FALabRepCo PRECISION Series Laboratory Freezers deliver superior cooling to laboratory environments. Engineered with variable speed compressors (VSCs), these units feature ultra-quiet operation and significant energy savings. VSCs optimize energy consumption by self-adjusting to cooling demands. These compressors also deliver enhanced system performance and provide a longer lifespan than other compressor variations.

$11,564.00 $8,904.28

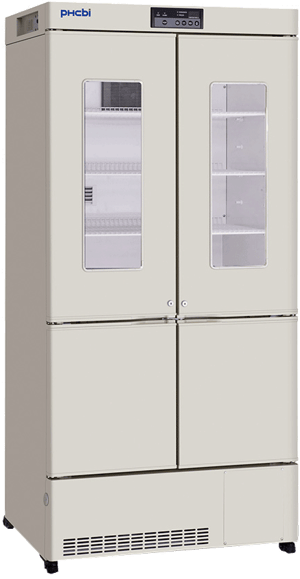

- External Dimensions: 54"W x 36 3/8" D x 81 1/2" H; 24 7/8" Door Swing; 59 3/8" Total open Depth

- Internal Dimensions: 49 1/8"W x 26 1/2" D x 59" H

- Storage capacity (cu. ft): 49

- Adjustable Temperature Range: -35°C to -15°C

- Door: Double Swing Solid Right and Left Hinged Door(s)

- Shelves: Ten adjustable, wire metal shelves with guard rail on back

- Drawers: Optional pull-out drawers available

- Mounting and Installation: 4 preinstalled swivel casters, front casters locking

- Interior lighting: Shielded, switched LED lighting, full coverage, balanced spectrum

- Airflow Management: Forced Air technology, patent pending

- External probe access: Rear wall port (3/4") dia.

- Insulation: Cabinet is foamed-in-place with EPA compliant high density urethane foam

- Exterior materials: White powder coated steel

- Interior materials: Stainless-steel

- Access control: Key Lock

- General warranty: Two (2) years parts and labor warranty

- Compressor warranty: Seven (7) years compressor warranty

- Product Weight (lbs): 506

- Shipping Weight (lbs): 625

- Rated Amperage: 7.6 Amps

- Power Plug/Power Cord: NEMA 5-15 plug

- Facility Electrical Requirement: 110-120V AC: 15 A (minimum)

- Agency Listing and Certification: ETL, C-ETL listed and certified to UL471 standard, hydrocarbon refrigerant safety

Performance

- Uniformity (Cabinet air): ±0.8

- Stability (Cabinet air): ±2.1

- Maximum temperature variation (Cabinet air): ±2.1

- Stability (Simulator ballast): Non-applicable

- Stability (Simulator bag): Non-applicable

- Temperature Rise after Short Door Openings: Non-applicable

- Recovery after Short Door Openings: Non-applicable

- Energy Consumption (KWh/day): 8.69

- Average Heat Rejection (BTU/hr): 2036

- Noise Pressure Level (dBA): 46 or less installed

- Pull down time to nominal operating temp: 153 min

Refrigeration System

- Compressor: Hermetic, variable speed (VSC). Rated speed range: 2000-4500 rpm

- Refrigerant: EPA SNAP compliant, R290

- Condenser: Fin and tube design, high efficiency fan

- Evaporator: Fin and tube design, high efficiency fan

- Defrost: Cycle optimized, zero energy

Controller, Configuration, Alarms and Monitoring

- Controller technology: Proportional Integral Derivative (PID) microprocessor with LCD display

- Battery Backup: 24V high-capacity battery, controller, all alarms active, temperature monitoring DAQ and event logging active on battery backup

- Display technology: Non-applicable

- Digital Communication: RS-485 (MODBUS)

- Data Transfer: USB port for data transfer and software updates

- Chart Recorder: Non-applicable

- Adjustable Temperature Range: -35°C to -15°C

- External alarm connection: State switching remote alarm contacts

- Alarms: Alarm logging (last 100 entries) with Visual and audible indicators: Power failure, Temperature sensor failure, Battery voltage monitor and replacement, High / Low temperature, Door ajar.

- Controller probe: Bottle with glass bead thermal media

- Disclaimers: Performance data acquired at 22°C ambient, 4°C nominal set point in an empty cabinet with drawers using validation ballast probes, during stabilized steady state operation and a DAQ sampling rate of one measurement every 10 seconds

- Uniformity is defined as the maximum variance in temperature across all probes at any point in time over the testing period

- Stability is defined as the maximum variance in temperature experienced by any single probe over the testing period

- Data per Energy Star test results or equivalent testing and calculation. Heat rejection based on daily averages, not continuous operation. Performance exceeds Energy Star requirements.

LP-49-FA Data Sheet

Download-

Hospital Grade Plug for Precision Series Refrigerators & Freezers

Item #: LP-HOSP-PLUG$112.00$86.24 -

10 Drawer Production Kit for LabRepCo Brand 49 Cu. Ft. PRECISION Series Refrigerators & Freezers

Item #: LP-DWRKIT-49$3,460.00$2,664.20 -

Ballast Kit for LabRepCo Brand Precision Series Refrigerators & Freezers

Item #: LP-LABBK$340.00$261.80 -

Mounting Anchors for LabRepCo Brand Precision Series Refrigerators & Freezers

Item #: LP-ANCHORKIT$156.00$120.12 -

GFCI Protected Duplex Electrical Outlet for LabRepCo Brand Precision Series Refrigerators & Freezers

Item #: LP-HC-EO115$886.00$682.22

Request a Proposal

Related Products

-

Item #: MPR-N450FSH-PA

$8,994.00$5,936.04Item #: MPR-N450FH-PA$9,481.00$6,257.46Item #: MPR-N250FH-PA$6,894.00$4,550.04Item #: MPR-N250FSH-PA$6,641.00$4,383.06Item #: MPR-715F-PA$12,031.00$7,940.46Submit a PO

Looking to submit a purchase order rather than buying online? Click on the Submit a PO button to learn more.

Sales & Support

Customer Service

Mon - Fri: 8AM to 5PM ET

101 Witmer Road, Suite 700

Horsham, PA 19044

Contact Sales

Need more information?

Would you like us to get in touch with you? Fill out the form below and we will contact you.