A centrifuge is a fundamental piece of equipment of laboratories. It can sometimes be a slightly overwhelming task to select the proper centrifuge for your specific application. From mini-centrifuges to high capacity centrifuges they come in a variety of sizes, capabilities and capacities. With the addition of features like refrigeration and network connections, it adds another layer to this almost daunting task.

We have broken down the selection process into 5 questions that we believe will make choosing a benchtop laboratory centrifuge easier for you. Read below to learn how to select the proper centrifuge for your application.

1) What are your speed requirements?

Centrifuge speeds are measured in RPM’s, or revolutions per minute, which describe how fast the centrifuges rotor revolves. They are also measured in RCF, or relative centrifugal force, which refers to the amount of force or acceleration that is exerted on the sample. As the speed of the rotation increases, denser materials move further away from the rotational axis and lighter materials move closer. Speed & force requirements will vary per application, therefore, obtaining the appropriate centrifuge that falls within your specific needs is the first crucial step when selecting a centrifuge.

2) What type of rotors do you need?

In addition to speed & force requirements, the rotor used is just as important; as you will need a rotor that is appropriate for your application within the speed range of the centrifuge and that you need. Rotors are used to support sample tubes during the operation of the centrifuge.

The two primary types of rotors are swinging bucket rotors and angular rotors. A swinging bucket rotor uses buckets to contain the sample tubes. The buckets spin at an increasing angle until it is almost perpendicular as the rotor speed increase. Swinging bucket rotors are ideal for low-speed, high capacity applications. A fixed angle rotor, the tubes are set at a 45 degree angle during the entirety of the rotation. Fixed angle rotors are ideal for high-speed, but smaller capacity samples, as they spin up to 3 or 4 times faster than swing bucket rotors.

3) Do your samples need to be refrigerated?

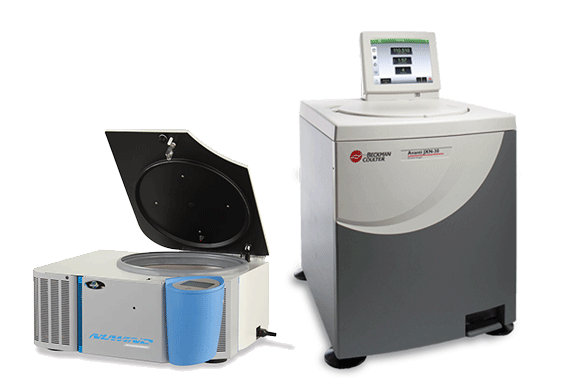

Primarily there are two types of centrifuges, ventilated and refrigerated. A ventilated centrifuge draws air into the bowl and then exhausts that air out of the unit. This will keep the contents of the bowl at a slightly higher than ambient temperature of the surrounding laboratory. It should also be noted that this temperature will increase during a typical 10-minute spin cycle, the increase, however, will range several degrees. Ventilated centrifuges are suitable for applications where precise temperature control is not critical.

For applications that require precise temperature control or a lower internal temperature during operation, refrigerated centrifuges are the best solution. Refrigerated centrifuges include cooling systems that lower and maintain preset temperatures during operation. They are also sealed and are able to moderate the heat generated by the rotors while operating at higher RPMs.

If temperature control is not required for your application, a ventilated centrifuge should be considered due to its lower cost and smaller footprint. Refrigerated centrifuges are larger than the equivalent ventilated centrifuge, and additional space is required for ventilation around the unit.

4) What size tubes will you be using in the centrifuge?

The capacity that you need your centrifuge to hold is essential to your selection process. Each centrifuge has a fixed number of sample tubes that it can hold during a run. Knowing how many tubes need to spin at one time, and what size those tubes will be, aids in centrifuge selection decisions. For example, angular rotors are intended for eight 50 mL tubes and can only be used for that size. A swinging bucket rotor can hold up to 20 tubes of the same size and can use inserts inside of the buckets to accommodate varying different sized tubes.

Also something to consider, the inserts or rotors you would be using are designed for use with either conical, round, or flat-bottom tubes only. It is important to use only correctly shaped tubes for the insert or rotor you select, so the tubes and samples are not only properly supported but also do not get crushed during operation.

5) How much bench-top or floor space do you have for your centrifuge?

Bench-top and floor space is usually at a premium in a laboratory, so the space you are able to spare is important when making your decision. The smaller centrifuges are typically only stored on a bench-top only, while mid-sized centrifuges can be used on either a bench-top or store d on the floor. The largest centrifuges are generally too large and are floor-mounted only. Floor-mounted centrifuges are typically smaller in length and width than bench-top centrifuges, but taller, while bench-top centrifuges are shorter, but often larger in length and width.

Summary

The overall choosing of your centrifuge should be done with careful consideration. While size, possible refrigeration and rotor capacity are to be considered there are other factors that should be taken account as well. The features of the unit, ease of use for the unit itself, and the technology offered. The warranty is important as well as the budget your lab has to spend.

Visit the centrifuge section of our website to select the proper centrifuge for your laboratory. If you still need help in choosing a centrifuge that is appropriate for your lab please contact us today to speak with a specialist.